We are trusted maintenance service provider established by ALL4JETS

with EASA, FAA, UK CAA & 2-REG (Guernsey) approvals

Your Global Aircraft Engineers

Aircraft Maintenance

We offer aircraft line maintenance in accordance with EASA, FAA, UK CAA & 2-REG (Guernsey) certification. We provide mobile solutions being able to support our customers globally with AOG, RTS or ferry flight projects. Moreover, we offer storage and parking services with preferred rates at chosen airports and are able to support storage maintenance at any other locations as per customer requirements.

We provide aircraft line maintenance for these aircraft types:

- Airbus A320 Family

- Airbus A320 Neo

- ATR 42-400/500 *

- ATR 72-100/200

- ATR 72-500 (212A) *

* including ‘600 version’

- Boeing 737NG

- Boeing 737MAX

- De Havilland DHC-8 Series 400 (Q400)

- Embraer ERJ 170/175

- Embraer ERJ 190/195

We provide BSI Services for the following aircraft types:

- AgustaWestland AW109

- Agusta A139

- Airbus A220

- Airbus A320 Family

- Airbus A320 Neo

- Airbus A310

- Airbus A330

- Airbus A340

- ATR 42/72

- Beechcraft 1900D

- Beechcraft B200

- Beechcraft B300

- Beechcraft C90A

- Boeing 737CL

- Boeing 737NG

- Boeing 737MAX

- Boeing 787 Dreamliner

- Boeing 757

- Boeing 767

- Boeing 777*

- Boeing 747

- Bombardier Dash 8 Q100

- Bombardier Dash 8 Q200

- Bombardier Dash 8 Q300

- Bombardier Dash 8 Q400

- Bombardier Challanger

- Bombardier Global Express

- Bombardier CRJ

* not valid for GE90 engine

- Cessna Citation X

- Cessna Caravan 208B

- Challenger 300*

* not valid for Honeywell engine

- Embraer EMB145

- Embraer ERJ170/175

- Embraer ERJ190/195

- Embraer E2 E-jets

- Eurocopter EC135

- Gulfstream V

- Gulfstream 550

- Gulfstream 650

- Pilatus PC-12

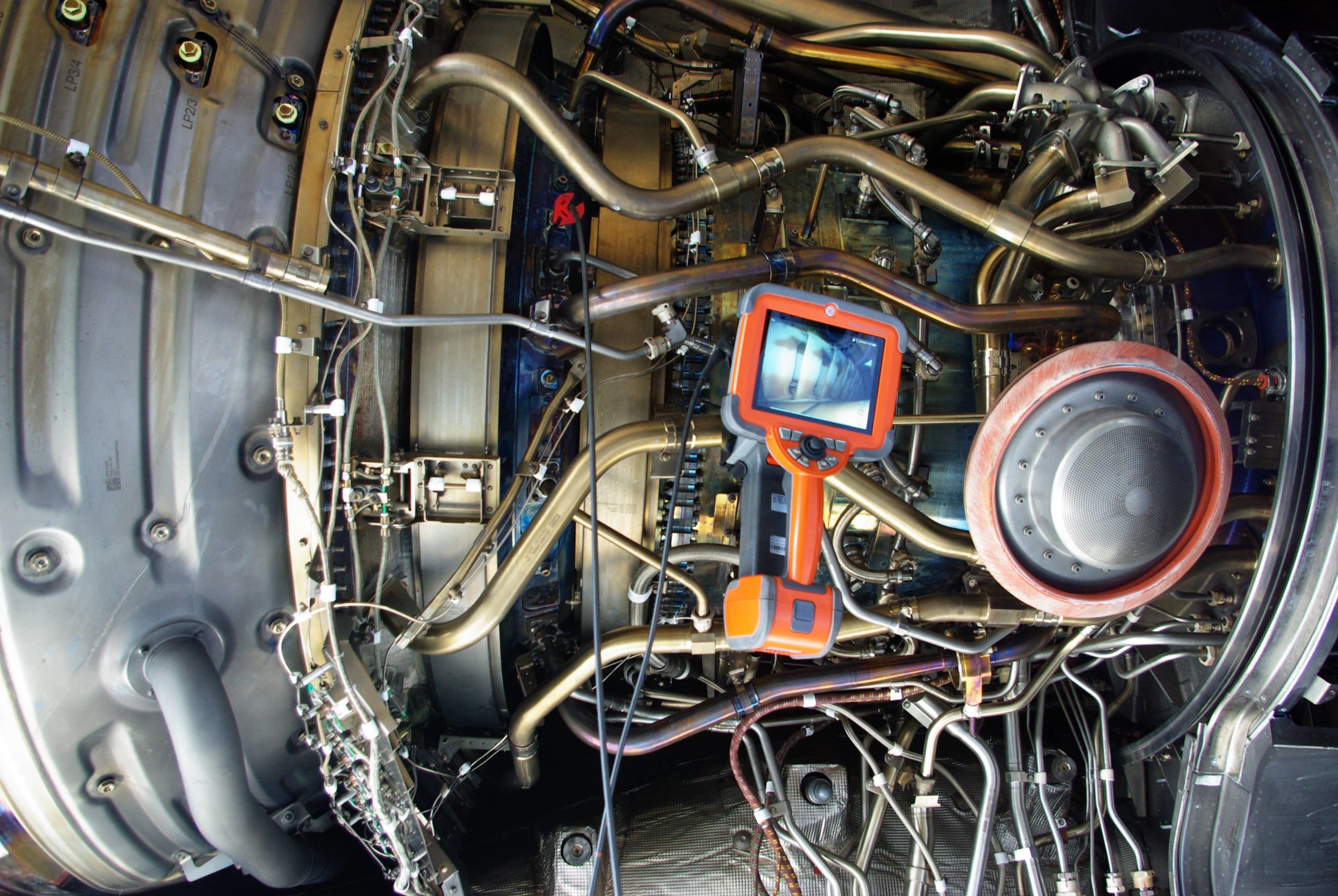

BSI

Certificates we can issue

Upon satisfactory completion of a borescope inspection or FADEC/thrust setting modification we are privileged to issue the EASA Form 1 certificate with dual FAA release and UK CAA Form 1.

Equipment we use

The highest available model of the Industrial Video Probe: Mentor Visual iQ, version ANALYZE with both working probes: 4 and 6 mm diameter, equipped with full Real 3D Measurement options and software capabilities. This configuration allows us to cover all the range of borescope inspections in our capability list.

For FADEC and thrust setting modifications we use the Teledyne Controls PMAT-2000 Portable Maintenance Access Terminal.